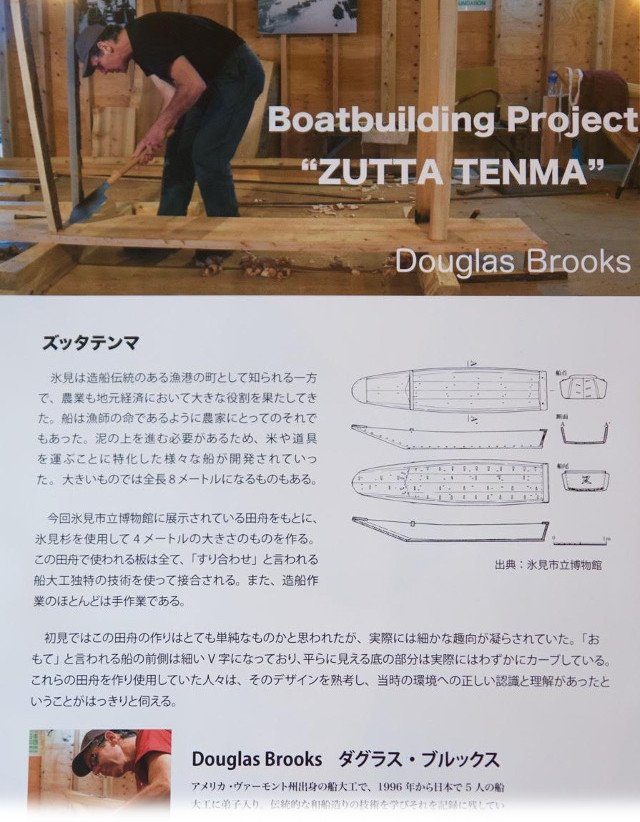

Zutta Tenma

-

In March of 2016 I built a small boat as an exhibition for himming.jp, a waterfront NPO located in Himi, Toyama Prefecture, Japan. I replicated a boat from the collection of the Himi Museum, a type once used in the extensive rice fields that surrounded the town. These boats were called zutta tenma. Tenmasen, or tenma, is a very common name for a small working boat in Japan. "Zutta" in the local dialect means to slide, referring to the need to slide these boats across the mud of the rice paddy.

-

Himi's rice paddies were so large they were connected by a series of waterways, therefore the rice harvest was carried by boats. There were three main sizes of zutta tenma and the one I built was among the smallest, five meters in length. The largest were eight meters. They all featured a slightly peaked, pram bow. In examining the boat at the museum I discovered some interesting construction details. The bottom is very slightly curved at the transom and the planks do not overlap the edges of the transom as in most boats. Instead the transom lays on the end grain of the side planks and nails are driven through the transom into the plank ends. The only other place I have seen this done is on the boats of Lake Biwa, Japan. Internal framing consists of a just a single beam mounted forward. All the material was cedar.

-

Himi is still an important fishing port and the sea boats built there do not reflect this type of construction. In talking to Himi's last two boatbuilders I learned that sea boats and rice field boats were built by different craftsmen, hence the different styles of construction. In the rest of Japan a rice field "boat" is really not much more than a sled, and too small for a person to ride in. Himi is a rare example of a place where these craft were true boats. Himming.jp launched the boat for their 2016 cherry blossom festival. Their fleet of replica boats traversed the cherry-lined canal that runs through the center of the city.

The finished zutta tenma, a type of rice field boat from Himi, Toyama.

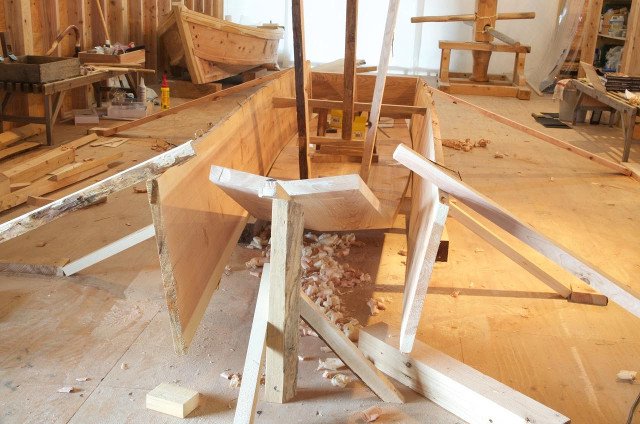

The backbone finished, with the side planks visible to the left. Note how the sides of the transom overhang the bottom. The sides will butt to the forward face of the transom.

The backbone, showing the peaked bow transom.

The planking only needs to be bent slightly to meet the bow.

The single beam is fitted into a shallow mortise in the side planking.

The mortises on the pram bow are visible. You can see where the two pieces of the bow are edge-nailed together as well as the nails connecting the bow to the bottom.

Like most Japanese boats, internal framing is minimal.

Display panel on the project, which was funded by the Tokyo-based Nippon Foundation.

The whole assembly is propped in place. Here the planks are being bent to shape.

The assembly has to be propped firmly so it doesn't move while nailing the sides.

A pair of temporary beams spread the hull to the proper width and plank angle.

The use of props in lieu of clamps is a hallmark of Japanese boatbuilding.